7 bags in 1 minute

We have a taste for it !Coffee and cocoa

Are you looking for an independent player who is at home in the world of coffee and cocoa logistics? Then you’ve come to the right place. We have many contacts in this industry and listen carefully to the issues that arise in the field of handling. That is how we come up with unique solutions. Our primary goal is not to maximize our profit, but to optimize your process.

Our aim is to keep your manual handling to a minimum while making efficiënt use of your available space. Result; no dependence on third parties, but always fully operational 24 hours a day. In addition, you comply with all health- and safety regulations in one fell swoop.

The heart of every project is the CargoPicker, a unique tool that makes unloading of your coffee- and cocoa bags effortless and very efficient. Processing high volumes in a short time is no problem. You can take the sustainable employability of operators to a higher level. So future-oriënted. And that’s how we assess every request; thinking about how to integrate the CargoPicker into a complete line that is future-proof.

Does this taste like more? Then read on.

Request quote

Turn keySustainable solutions

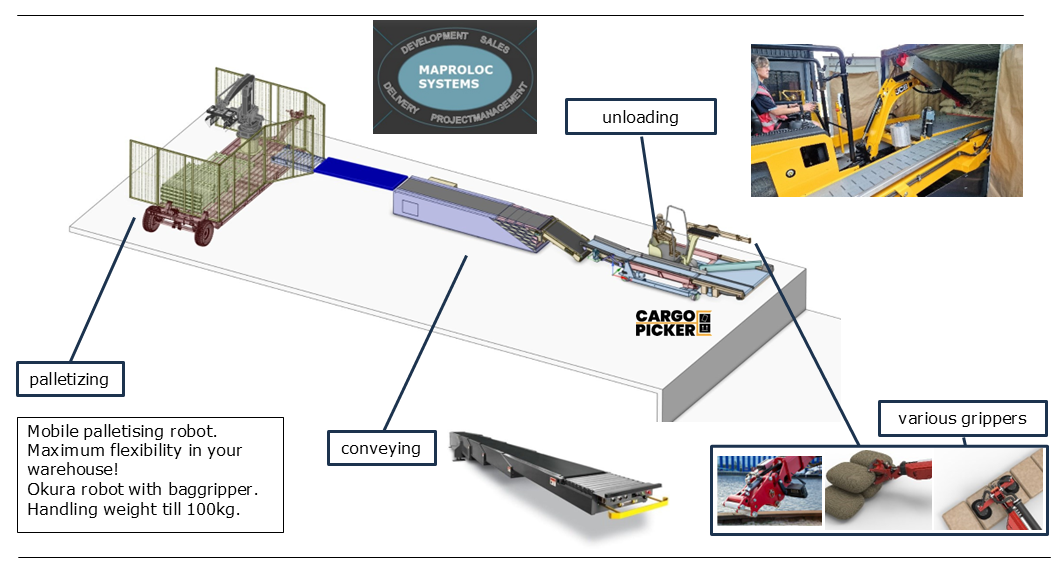

An automated unloading process guarantees profits on all fronts; labor, manhours, an uninterrupted process and safety. Very efficient. Together with partners we develop dedicated turn-key solutions in which the CargoPicker is an indispensable component.

We recently expanded our program with a unique mobile palletizing solution. The heart is a robust Okura robot. See also Okura robot technology Standard delivered with a baggripper. A compact and reliable system. Its strong point is its mobility by means of a forklift truck. That creates maximum flexibility in choosing unloading locations. No more wasting times by changing containers.

Due to the great mobility and flexibility of our systems, various layouts are possible. The turnkey delivery from our factory guarantees fast installation and commissioning on site.

Contact us for all info and details.

More information

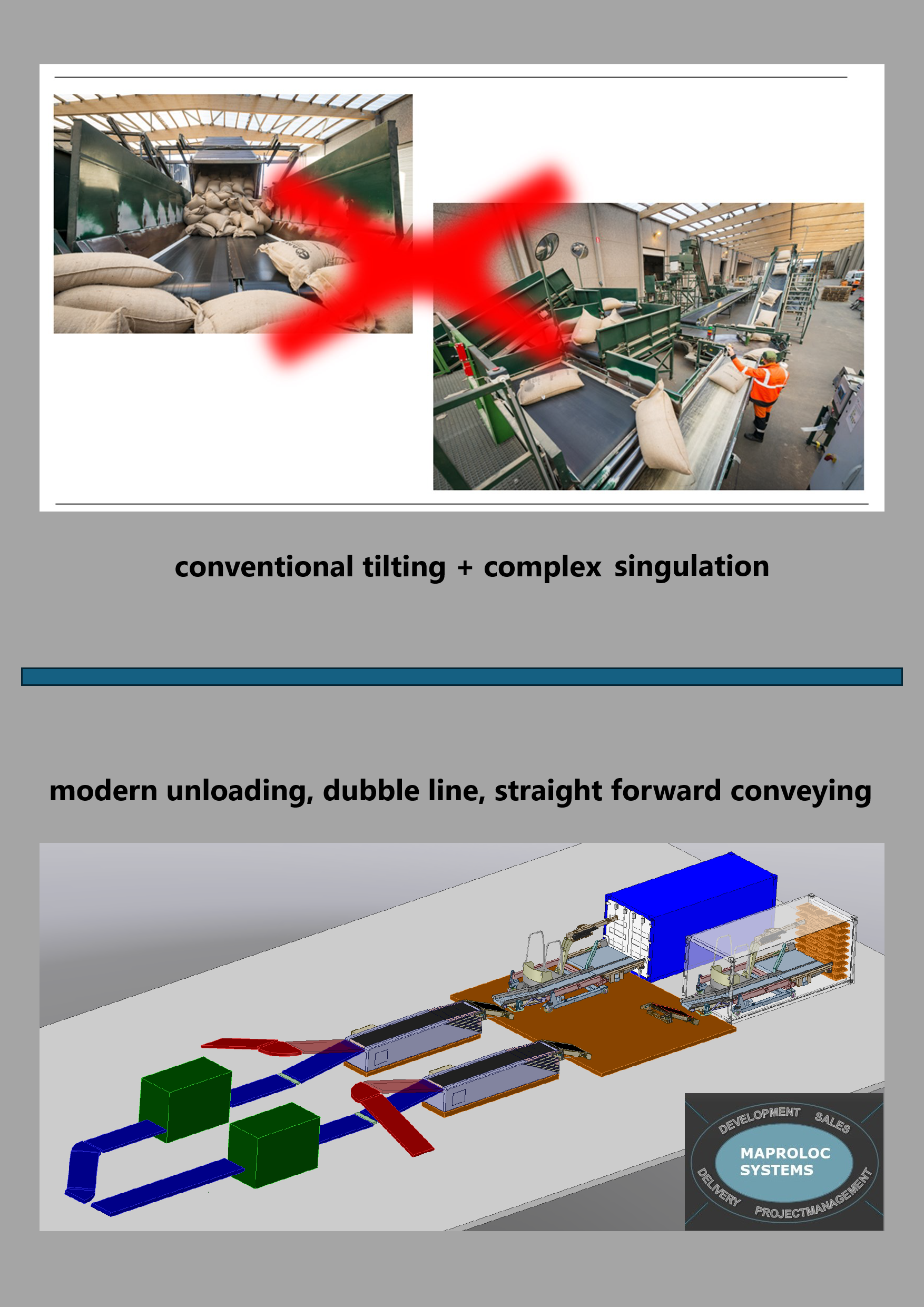

handling jute bagsprevent damage, choose maximum control

With the unique modular principle of the CargoPicker as a basis, it is also easy to scale up to a very interesting alternative for container tipping systems.

The basis: 2 CargoPickers followed by 2 telescopic conveyors.

The goal: continuous unloading of 2 containers simultaneously, connected to 1 high-speed palletizer or robot.

You will be amazed at the advantages this provides.

The TWENTY advantages of choosing CargoPickers instead of a tipping installation

- Handling of all types of jute bags, including Grainpro’s

- CargoPicker constructed with proven, solid crane technology and maintenance-free conveyors

- Freely movable and therefore very flexible in use

- Unique, multi-functional and fast hydraulic gripper system

- Picking position for bags at the front so that closed deck loads are not a problem

- Bags are pulled onto the conveyor during stacking, so no lifting is required

- Quick change of gripper fingers when handling grain pro’s or fragile bags

- Operator control with 2 joysticks and foot pedal

- Servo hydraulic system allowing precise operation

- Operator can see each bag allowing full control of the entire process from unloading. Visual operator inspection possible at the beginning of the unloading process.

- Choice of unloading after rejection e.g. with push button in cabin

- Bags are not damaged by gripper

- Bags are always fed lengthwise (SSL)

- Low space requirements due to compact design

- Very low maintenance costs

- CargoPicker and truckloader electrically cross-moving (optional).

- Time saving when moving crosswise. Quick change to next container

- Optional unloading from chassis possible. See under

- When unloading from chassis, great savings on hours container stacker with driver

- Conclusion: Full control of unloading process from start to finish!

Phased investment is possible. Expansion with, for example, weighing, scanning and control systems + stations for sampling.

Strong price-performance ratio!

Request quote

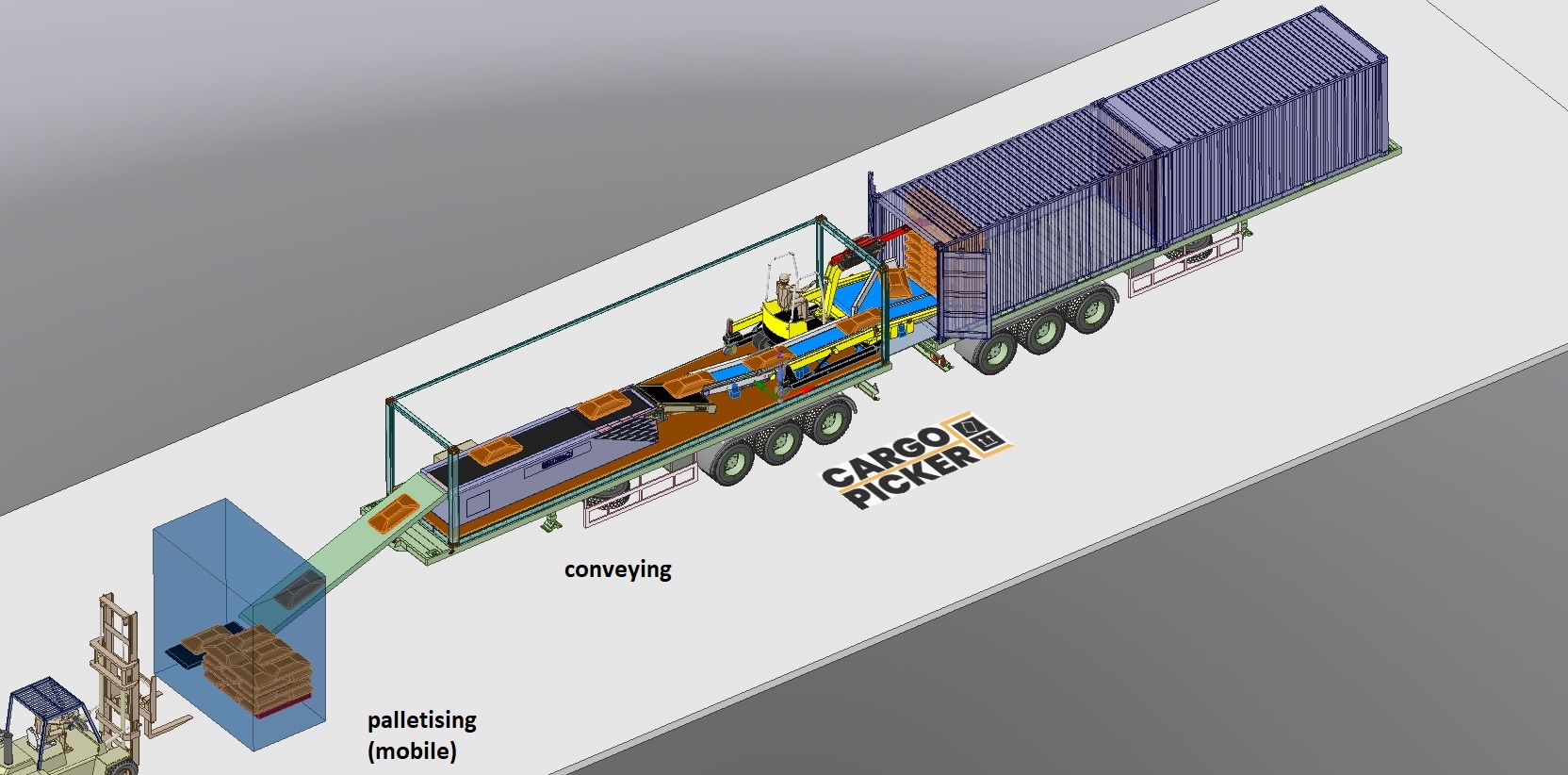

mobile solutionMaximum flexibility

For locations without loading docks. For this application we place the CargoPicker and a connecting telescopic conveyor in a seacontainer. In combination with a mobile robot cell, specially developed for this purpose (see above), the turnover speed of the entire unloading process will significantly increase.

Compact: fits in a standard 40” container with dubble doors.

Mobile: container to be placed on a chassis on same level as connected container with bags, at any location.

Fast: containers can be unloaded directly from the chassis.

Savings: no transshipment costs with container stackers to place the container on the ground.

Check on Youtube Mobile application Live

Request quote